Every step, from sketching to pattern making, from cutting to sewing, and then on to finishing, ironing, quality control, and shipping, takes place within the company, thus ensuring protection and safeguarding of the products being crafted.

The creation of the pattern is the starting point in the making of a prototype but is also the heritage of a fashion company.

The pattern room is the valuable archive to access when starting production.

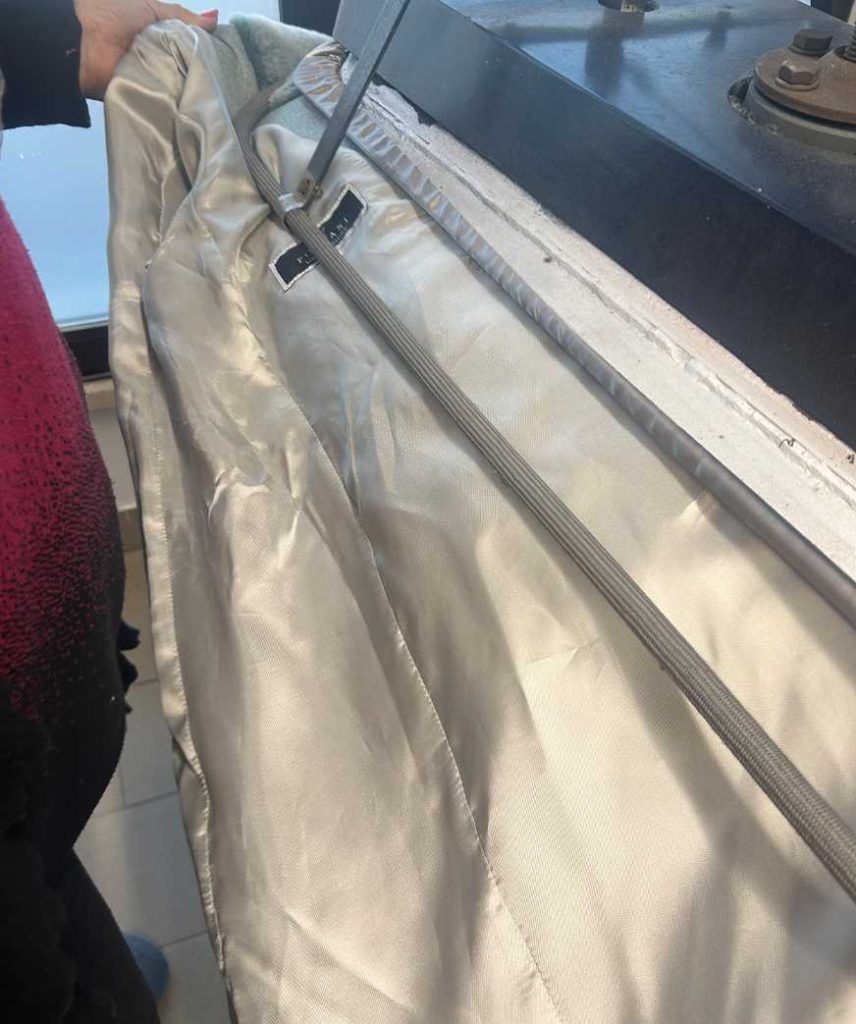

Working with fine materials and creating complex garments, the use of a test canvas ensures the perfection of the finished product, especially in terms of its fit.

The cutting of materials, which occurs subsequent to the selection of the leathers as well as the inspection of the fabrics, concludes the design phase of a prototype.

With sewing, we enter the actual phase of creating the garment by assembling the various cut pieces.

The satisfaction of seeing what was just an idea a few days before come to fruition is truly immense.

Depending on the materials to be sewn, there is an appropriate machine, but always very skilled hands.

This phase, although it may seem trivial, is actually very delicate because we often find ourselves ironing a garment made of different materials that require different types of ironing: the press, steam, traditional iron… and only highly specialized personnel can do it properly.

After a thorough final check, a true work of art can finally be presented.

Fontani SRL

Via Tosco Romagnola Sud, 35, 50056 Montelupo F.no (FI) Italia

info@lineafontani.it certopiano@pec.it

P.IVA 05637940486

sito web creato da Outside The Box srl, Firenze